Activities

CIRC-eV Laboratory’s mission is developing a new Circular Factory concept to help the manufacturing industry recover and reuse components from hybrid and electric vehicles and promote new circular economy models for sustainable mobility. CIRC-eV is the first European laboratory dedicated to the Circular Factory concept.

It integrates disassembly, testing, reassembly and recycling of materials within the same structure, to design and enable sustainable circular economy solutions for the e-mobility sector. CIRC-eV will be equipped with Key Enabling Technologies (KET), focusing on the initial configuration and the most critical component for sustainable e-mobility – lithium-ion batteries.

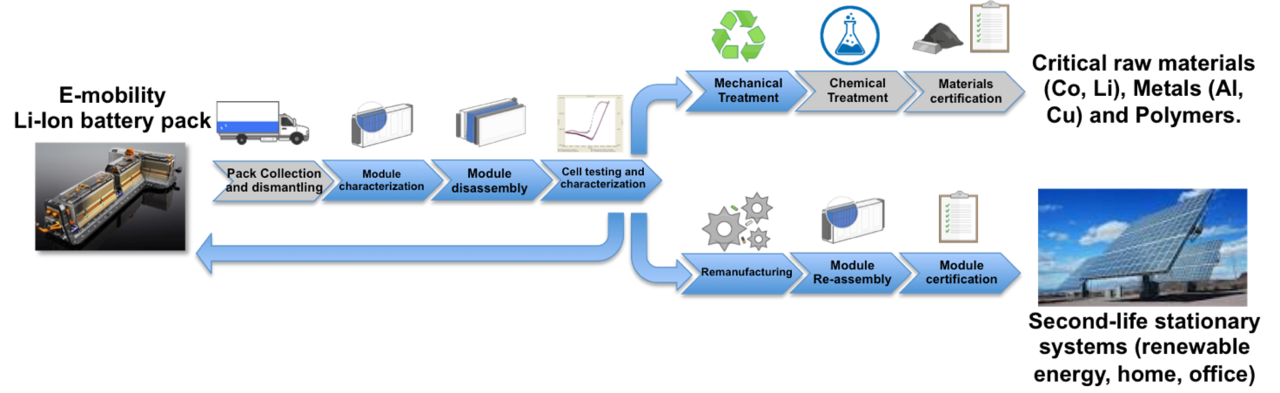

The objective is to demonstrate the technical and financial feasibility of the circular process chain represented in Figure 1.

The most interesting strategy for automotive lithium-ion batteries is related to remanufacturing and reuse of disassembled cells. Cells with adequate residual properties will be reused in second-life applications using a cross-sector approach. Regenerated battery packs could be used for storage to support systems from renewable sources or inside living spaces (home, office). Cells that do not maintain sufficient secondary post-use properties will be destined for recycling to recover high value-added materials. Developing enabling technologies and decision-support systems will enable the best strategy for the management of post-use cells to be chosen based on residual performance. On a technical-scientific level, macro-challenges of the CIRC-eV laboratory are linked to:

- Design and development of a safe cell disassembly process and systems, with the appropriate level of flexibility to handle the wide variety of battery module types.

- Methods and procedures to assess the state of health (SoH - State of Health) of the cells, define how they degrade and estimate their residual useful life, allowing their application in second-life modules with certified performance.

- Development of methods to support decisions on cell selection and reassembly of knowledge-based and data-driven modules, aimed at creating second-life modules optimised depending on the most suitable application.

- Development of control systems (BMS - Battery Management System) which can meet the new specifications and requirements of the reconverted second-life modules.

- Design and development of highly selective mechanical pre-treatments to recover valuable materials and isolate the active fraction (Black Mass), to enable the recovery of key materials using hydrometallurgical treatments.

The CIRC-eV pilot factory will support multidisciplinary research and innovation activities to solve these challenges by developing methods and technological solutions with high potential for technology transfer to industry, able to demonstrate the feasibility and financial, environmental and social impact of a new circular business model for sustainable mobility.

Equipment

The CIRC-eV laboratory uses a pilot factory, and integrates technologies related to the mechanical handling, testing and pre-treatment of lithium-ion batteries from electric mobility. CIRC-eV has three main functional areas, and each is a group of processes and related physical technologies that contribute to the implementation of a specific function.

The three functional areas are as follows:

- Mechanical processes: A functional area which performs the operations that regenerate second-life modules through the reuse of cells and material recovery. All the mechanical processes of disassembly, reassembly, cutting, grinding and separation are integrated in this area. The transport units for parts and materials for the automatic connection of the different process steps are integrated in this area. The semi-automatic disassembly and reassembly line includes robotic units for cell handling and connection disassembly.

- Li-Ion cell testing: A functional area which tests modules and disassembled cells and analyses residual properties and second-life applications in automotive modules or stationary applications. Various testing technologies to identify the most appropriate procedure for future large-scale use are integrated in this area. This functional area includes a cycler for modules (up to 60V/200A) and single cells (5V/100A) multi-channel, for battery performance and SoH using advanced diagnostics such as Incremental Capacity (IC) or Electrochemical Impedance Spectroscopy (EIS).

- Data analysis and modelling: A functional area enables the flow of information to the processes implemented in the other areas, through advanced data collection, modelling and simulation techniques. In this area several sensors, modelling environments and cyber-physical systems are integrated to ensure the safe and highly efficient execution of CIRC-eV transformation processes.

Services provided

CIRC-eV includes multidisciplinary expertise and technological capabilities to support research, development, and engineering of innovative circular economy solutions for the automotive and energy storage sectors.

CIRC-eV services include:

- Development and technological and financial feasibility studies of circular economy strategies (disassembly, recycling and reconditioning) of high added value products. The available technologies make it possible to safely test various disassembly, re-assembly and mechanical recycling strategies with a high level of automation.

- Study and development of procedures and protocols for testing of residual properties of modules and individual cells from Li-Ion batteries.

- Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) studies to quantify the impact related to the developed circular economy strategies.

- Study and analysis of specific second-life strategies and applications, according to the product’s state of health.

- Development of re-design solutions for products and components to favour circular business models with higher added value.

- Study of reverse logistics to support the introduction of the circular business model enabled by CIRC-eV solutions.